About me

JN TATA Scholar | Roboticists | Solidworks Leader

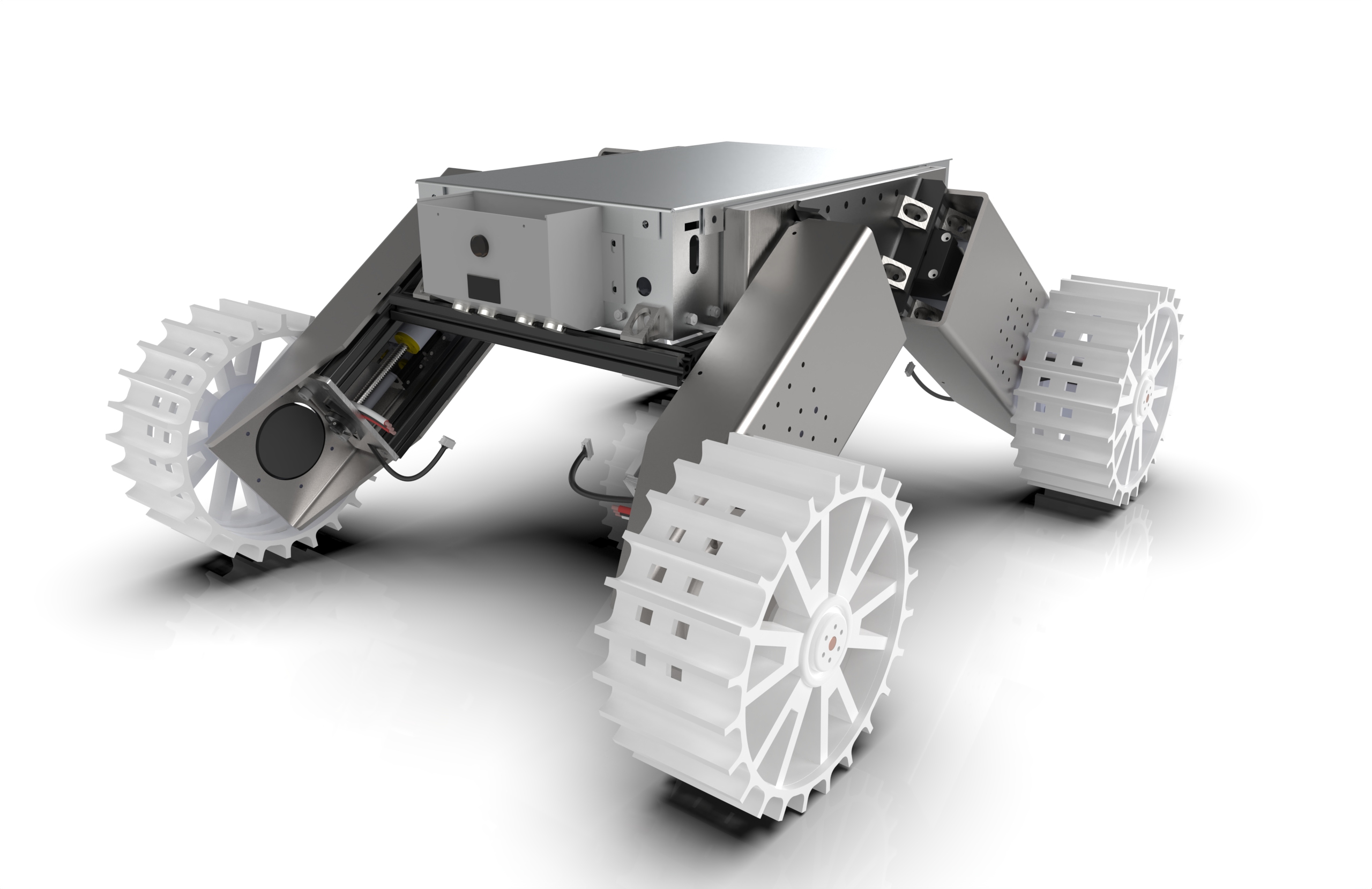

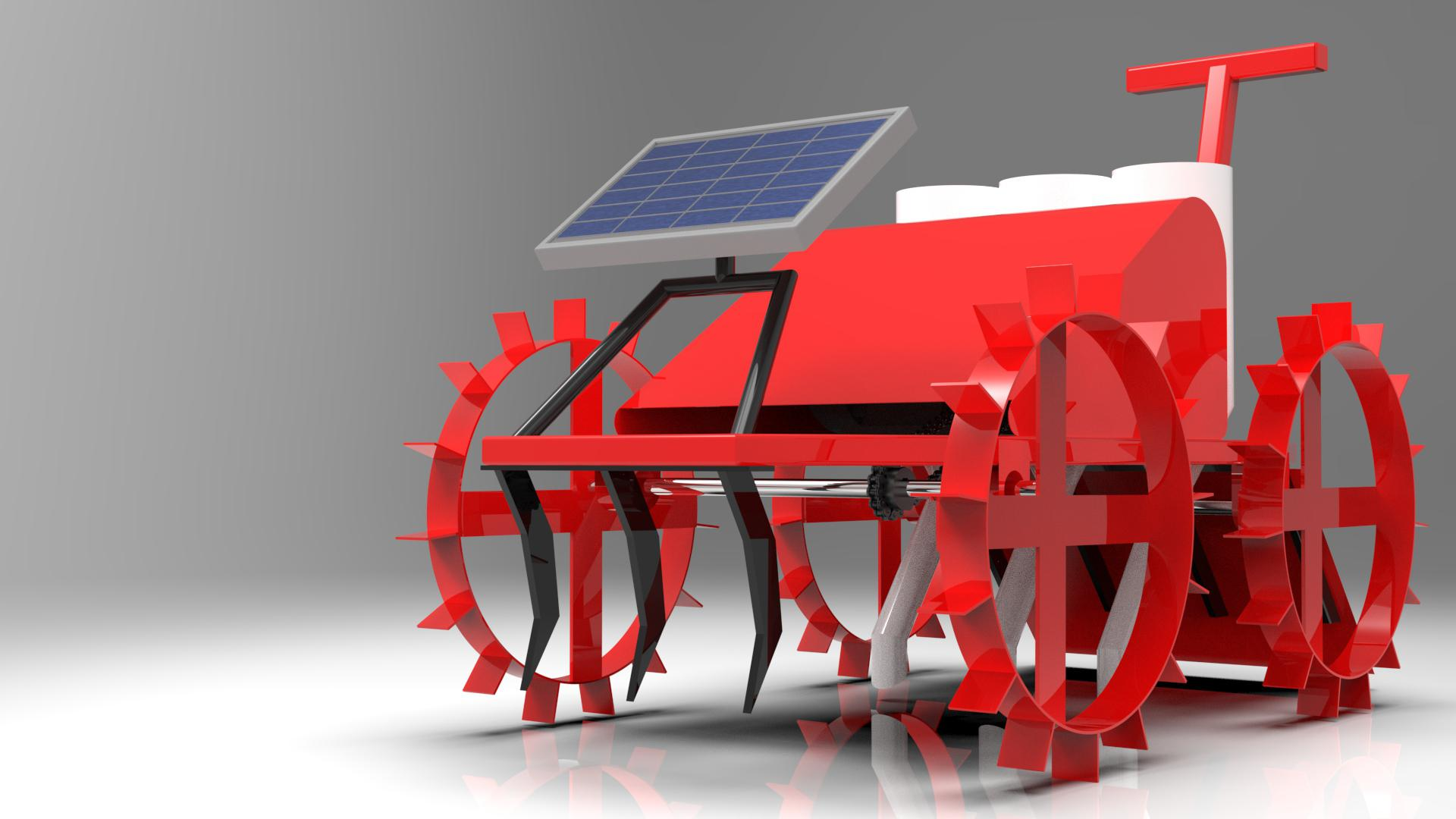

Motivated, efficient and organized with a passion for learning new skills and an inquisitive mind. With my out-of-the-box thinking and problem-solving skills, I hope to become a successful Robotics engineer. Using my experience with robotics, ROS programming, CAD design, and embedded systems, I can effectively develop space robotics.

Time and again, people discuss the future and how they wish things would be. Nevertheless, I believe that inventing the future is the best way to predict it. The desire to create a future where Robots can relieve human workers of quotidian tasks and empower us to go beyond our limitations has been the driving force behind my pursuit of a roboticist career.

What i'm doing

-

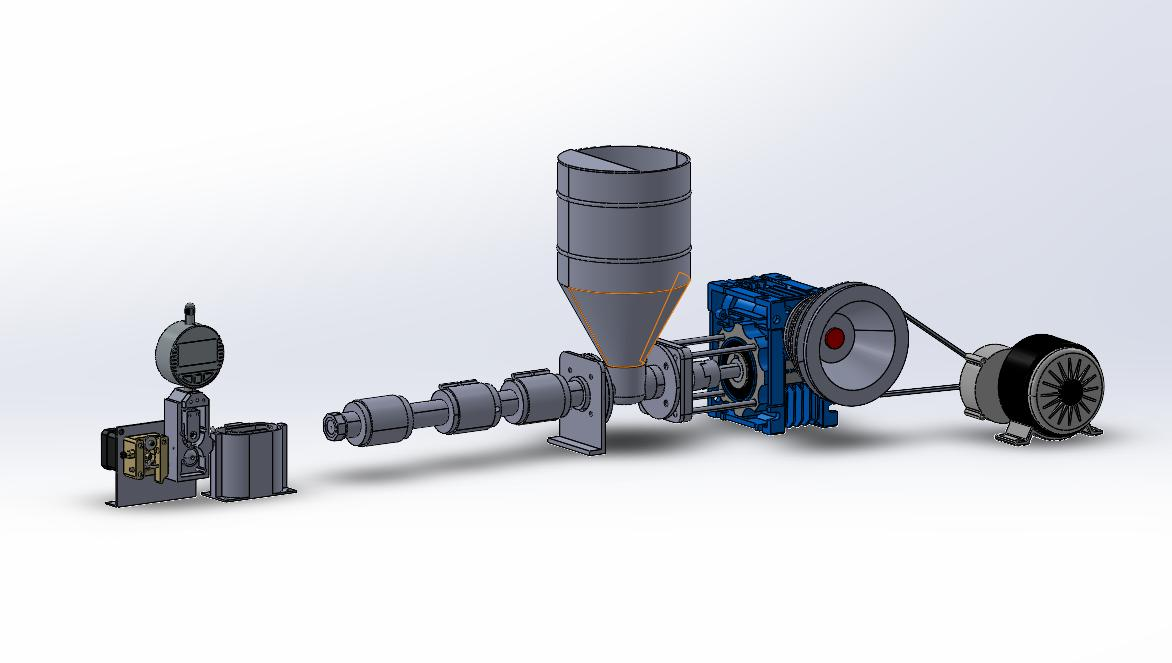

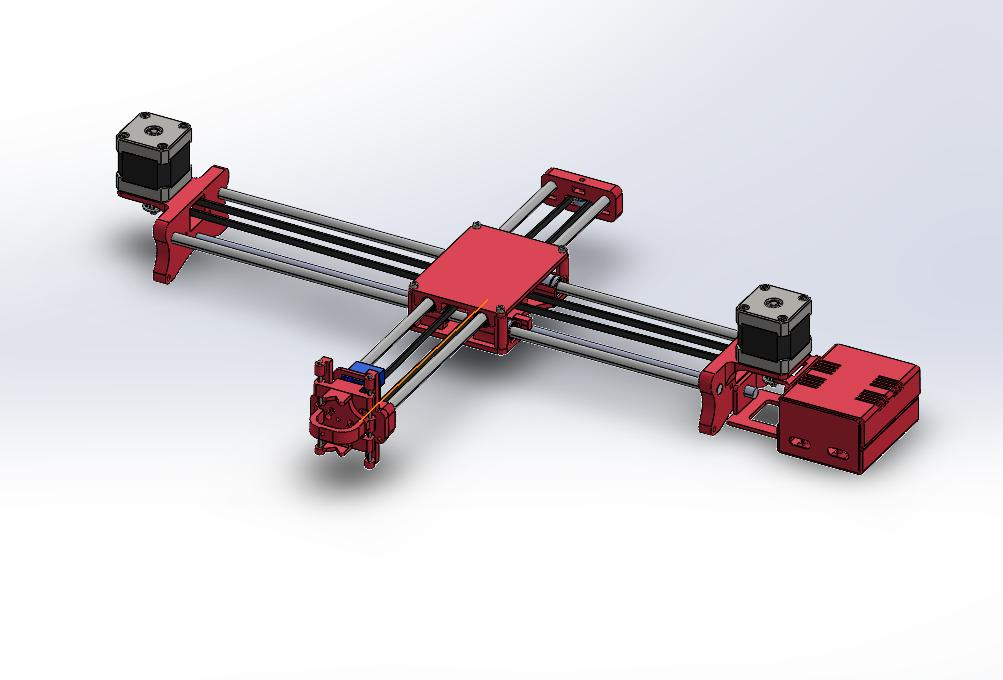

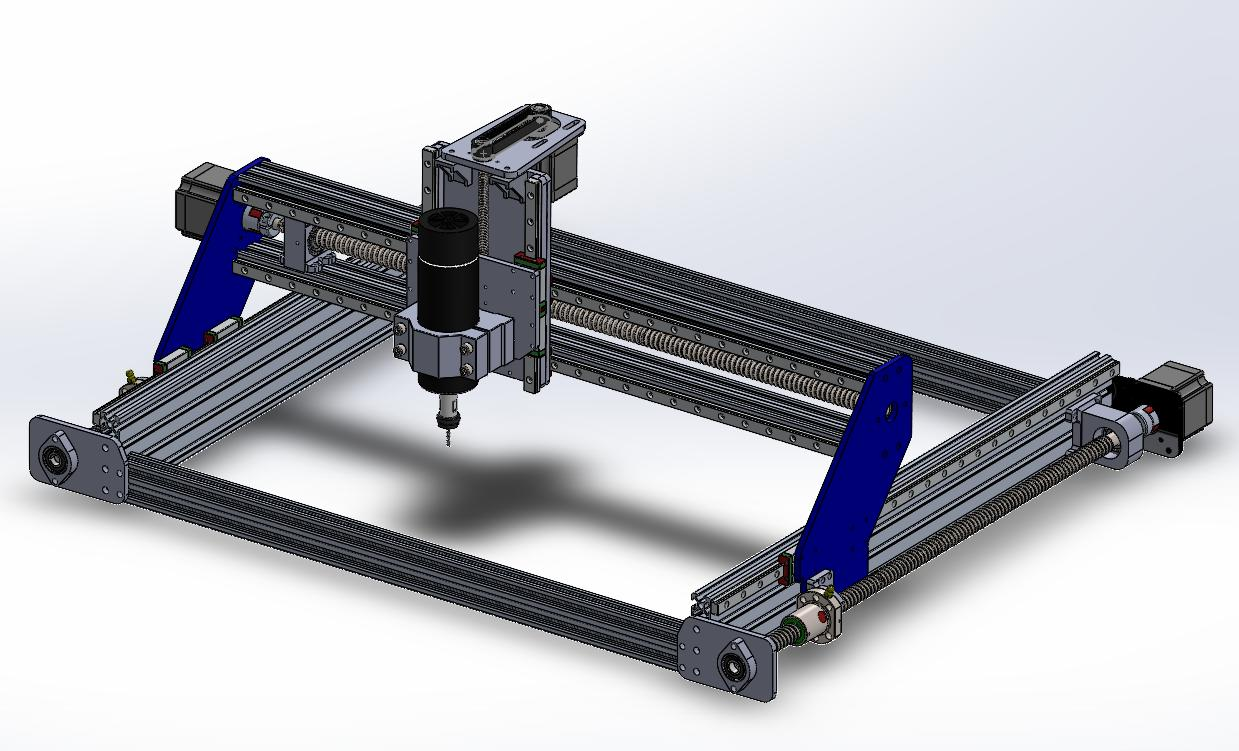

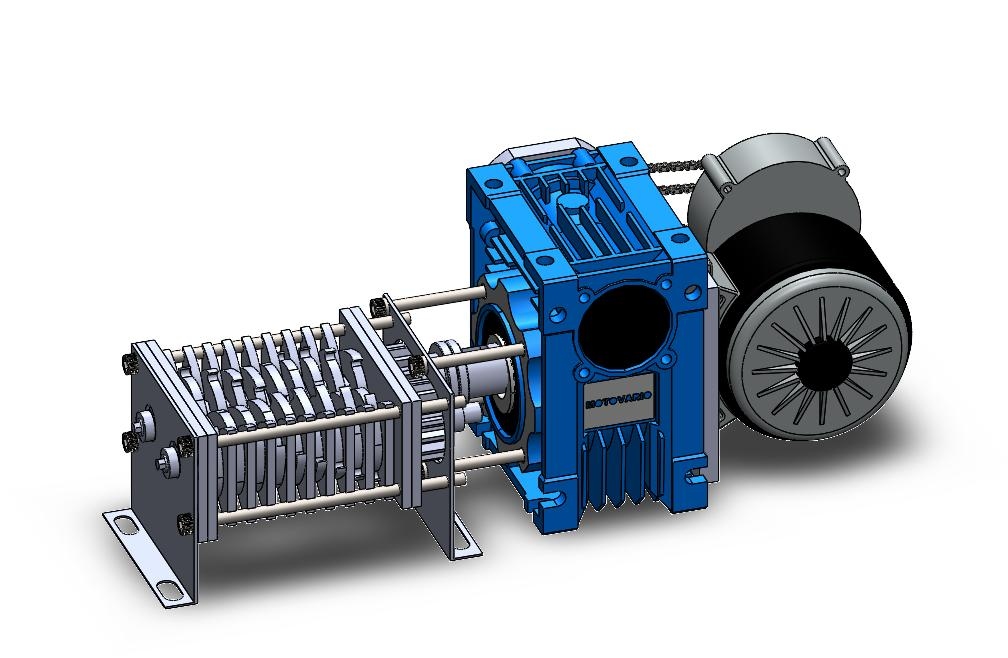

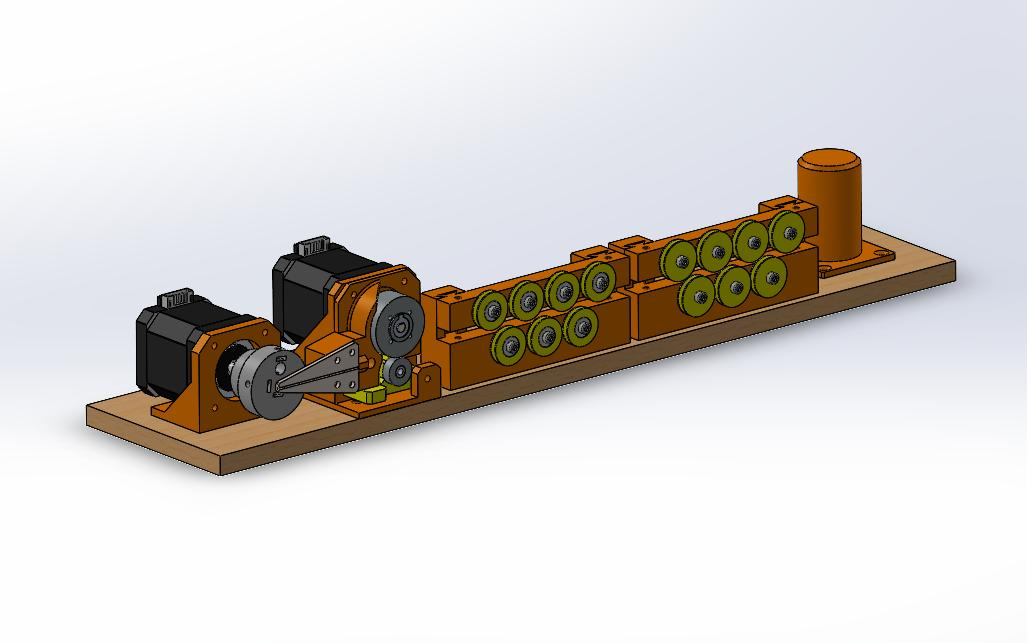

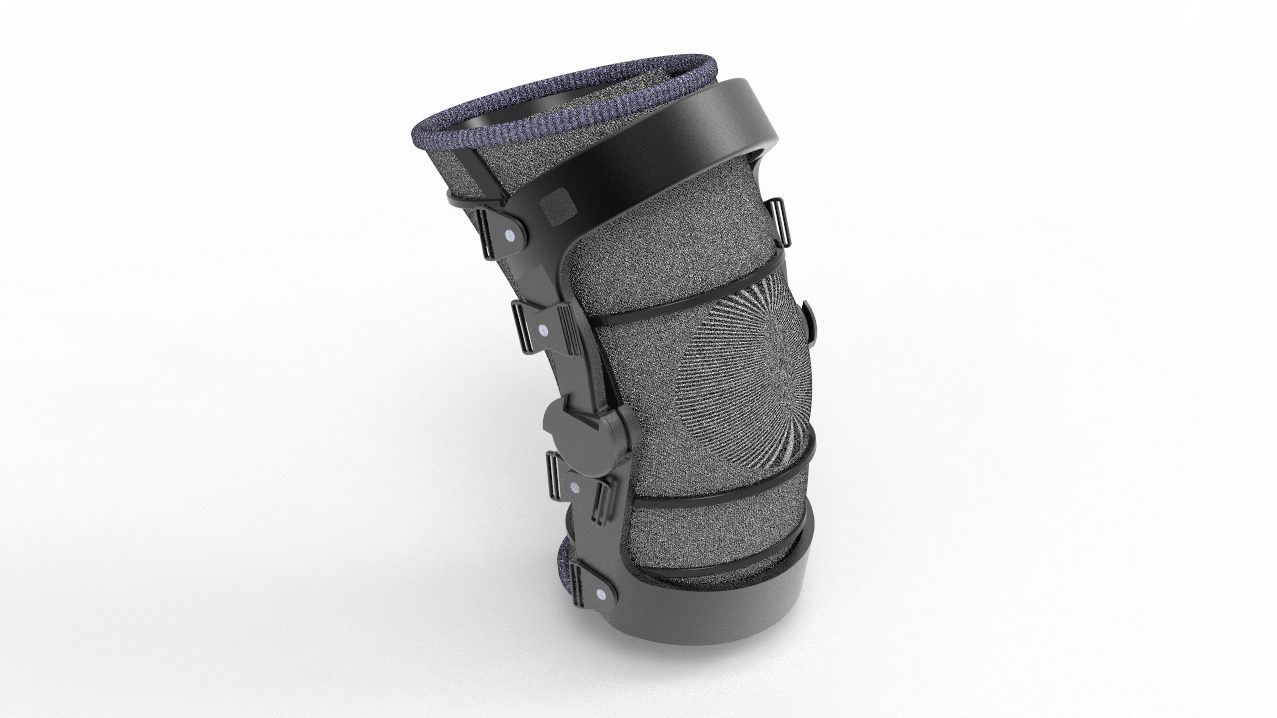

CAD Designing

Designing products before they're manufactured.

-

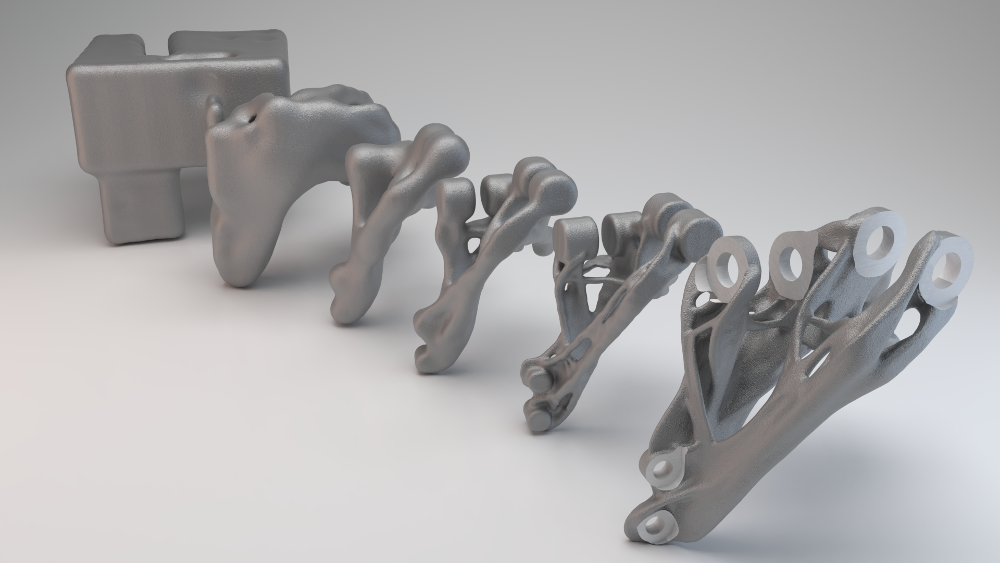

FEA & CFD simulation

Using softwares to prove my designs work!

-

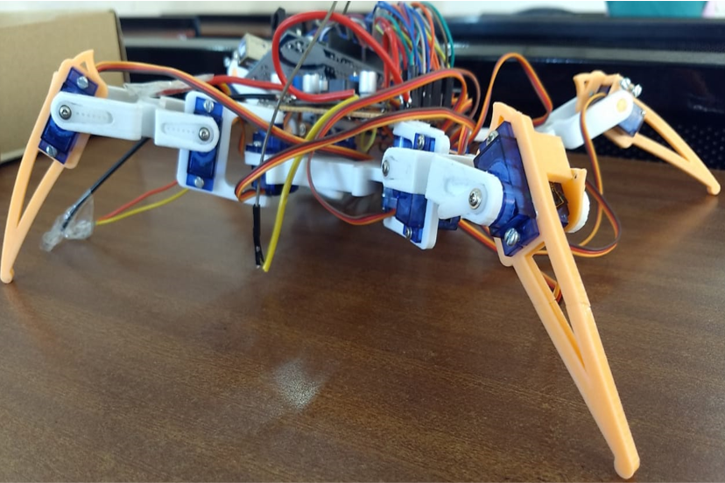

Rapid Prototyping

Utilizing 3D printers and some handyman skills for POCs.

-

DFMA and GD&T

Preparing for manufaturing with precision and accuracy

Testimonials

.jpeg)